Description

Vacuum oven is a kind of box-type drying equipment which can dry materials at low temperature.Its working principle is to use a vacuum pump to pump air and dehumidify,then the working chamber forms a vacuum state, reduce the boiling point of water, and accelerate the speed of drying.It has the advantages of fast drying speed, small pollution and no damage to the internal quality of the dried goods.Widely used in medicine, food, light industry, chemical industry, electronics and other industries for drying.

Vacuum drying is to put raw material under the state of vacuum for heating and drying. If use vacuum to pump air and humidity out, the dry speed will be faster.

Note: if use condenser, the solvent in raw material can be recovered. If the solvent is water, condenser might be canceled and the investment and every could be saved. it use SK series water ring vacuum pump sets, condensate can not be used and the investment could be saved .

Features

1. Under the condition of vacuum, the boiling point of raw material will decrease and make the pushing force become greater. Therefore for a certain amount of heat radiation, the conducting area of evaporator can be saved.

2. The heat source for operation of evaporation may be low pressure steam or surplus heat steam.

3. The heat loss of evaporator is less;

4. Before drying, the treatment of disinfection may be carried out. During the period of drying, there is no impurity material. It is in conformity with the requirement of GMP;

5. It belongs to static drier. So the shape of raw material to be dried can not be destroyed.

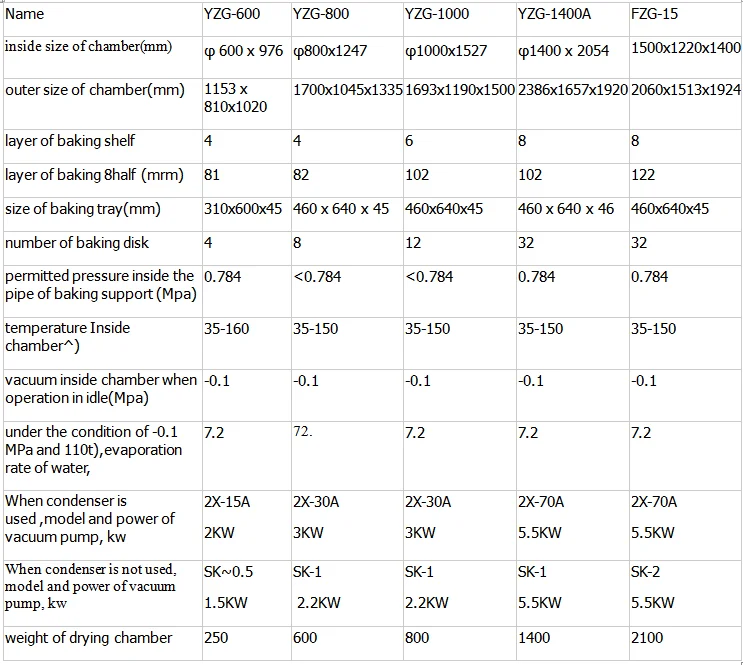

Products Parameter